CNC Machining

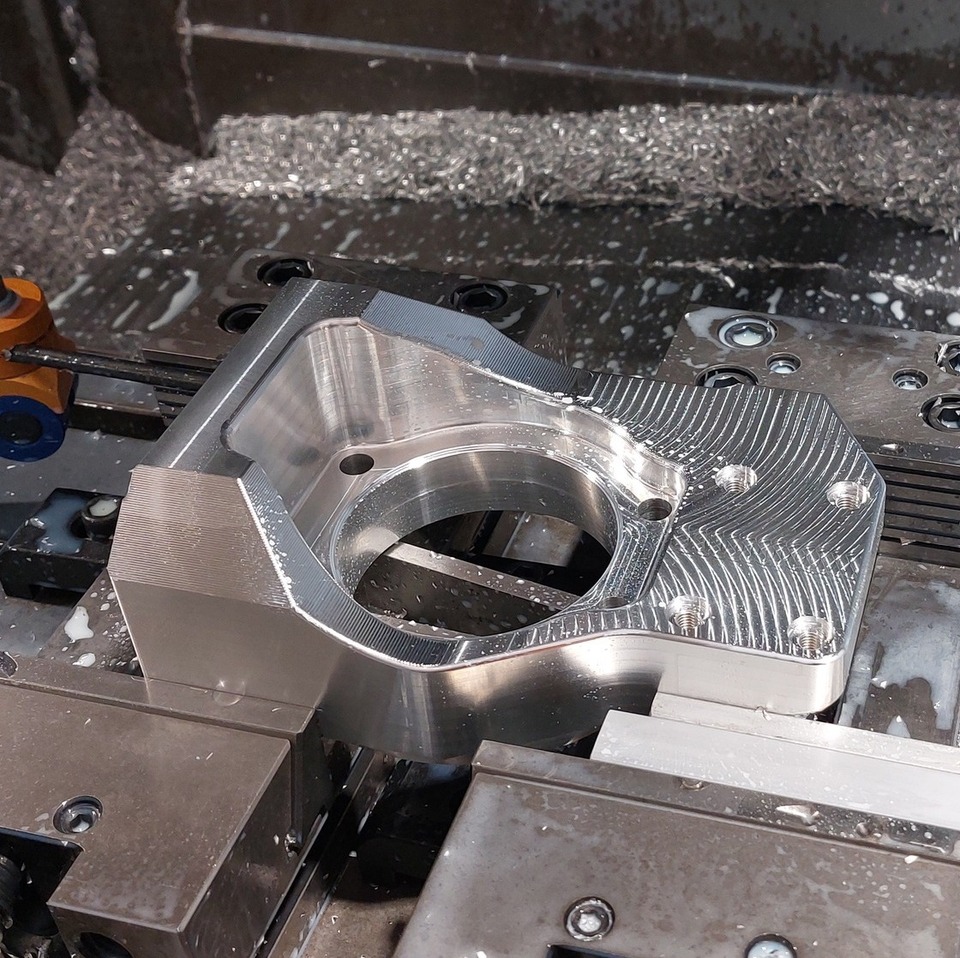

CNC Milling

Our CNC milling machine has a machining envelope of 1000 x 500 x 600mm (xyz). We can sometimes machine parts longer than 1m (for example machining a 100mm keyway in the end of a 1.5m shaft), depending on the design.

We regularly machine aluminium, steel, stainless steel and engineering plastics.

For most CNC Milling parts we usually require a 3D CAD file (such as a .step, .iges or .x_t file. .STL files are not normally suitable) and a drawing (usually a PDF). The drawing should indicate the material, any tolerances and also have any tapped holes or threads

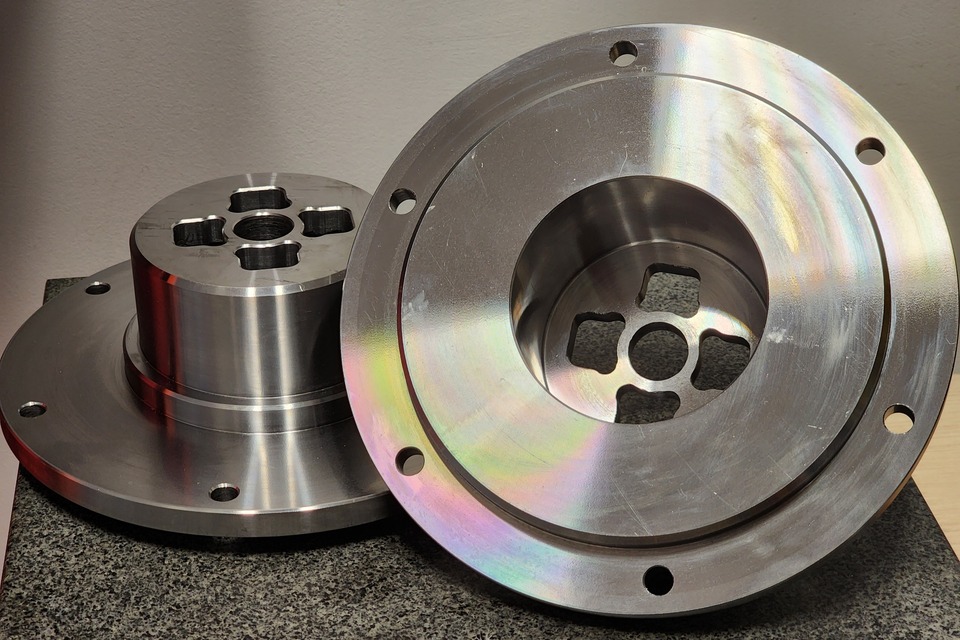

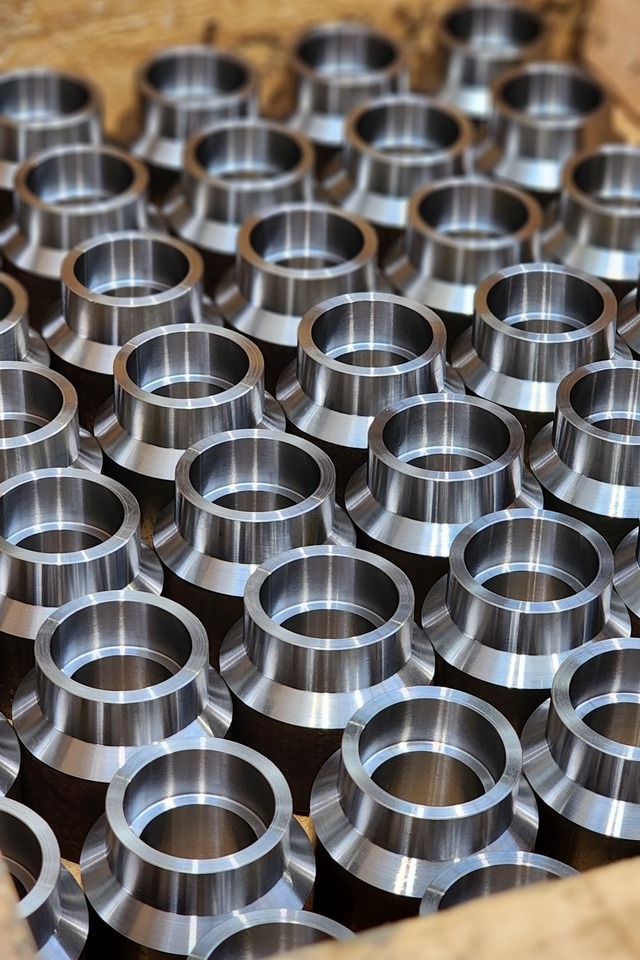

CNC Turning

Our CNC lathe can machine up to Ø200mm diameter. With live tooling , a bar feeder and a y axis we can also do production milling or fourth axis work.

Our CNC lathe can machine up to Ø200mm diameter. We regularly turn aluminium, steel, stainless steel and engineering plastics.

Pricing

Pricing jobs for CNC machining is typically composed of 3-4 parts.

- Programming cost - once off. This involves writing the G code to automate the machines. CNC turning simple parts this may be as little as $20. If you have a complicated milling job this could be closer to $200. The more complex the part, the more time it will take to program.

- Fixtures - once off. Most parts require a 2nd operation, some require more. Depending on the complexity of a part, sometimes a custom fixture is required. A lot of the time a fixture isn't necessary. We can make design pointers to make the parts simpler to machine and eliminate the need for a fixture.

- Setup - once per batch. Setup costs cover the time to get the machine ready, load the program and the required tools or work holding. This can typically be between 15 minutes to 2 hours.

- Parts - the cost per item to machine the item, including material.

|

© Copyright Outsource Engineering |